Prepare

Examine

Evaluate

The strength of electrochemistry

In terms of electrochemical characterisation, ELCAT can offer all electrochemical characterisation methods (CV, LSV, RDE, CA, CP, EIS), potentiostats, bi-directional current sources and boosters combined with several in-line analysis techniques (GC-MS, LC-MS, ICP-MS) necessary to qualitatively and quantitatively determine the electrochemical performance. It can use this plethora of methods and instruments to evaluate both the kinetic and the mass transfer related parameters of any electrochemical reaction as well as to determine the specific resistances of each component.

The strength of electrochemistry

In terms of electrochemical characterisation, ELCAT can offer all electrochemical characterisation methods (CV, LSV, RDE, CA, CP, EIS), potentiostats, bi-directional current sources and boosters combined with several in-line analysis techniques (GC-MS, LC-MS, ICP-MS) necessary to qualitatively and quantitatively determine the electrochemical performance. It can use this plethora of methods and instruments to evaluate both the kinetic and the mass transfer related parameters of any electrochemical reaction as well as to determine the specific resistances of each component.

Our machines and specifications

The main expertise of ELCAT is electrochemistry and for this reason ELCAT has a broad plethora of potentiostats and power sources available at its disposal from the most renowned brands (Metrohm, Biologic, Ametek). With it ELCAT is able to register and apply currents from pA level up to 100A and potentials from nV level up to 80V with an accuracy of 100µV to accurately monitor the electrochemical reactor performance. In addition, several of their potentiostats are also capable of performing electrochemical impedance spectroscopy measurements with a frequency range from 10µHz to 10 MHz at a maximum load of 10V and 6A. The latter enables us to determine the internal resistances in the reactors and device strategies to lower them.

The main expertise of ELCAT is electrochemistry and for this reason ELCAT has a broad plethora of potentiostats and power sources available at its disposal from the most renowned brands (Metrohm, Biologic, Ametek). With it ELCAT is able to register and apply currents from pA level up to 100A and potentials from nV level up to 80V with an accuracy of 100µV to accurately monitor the electrochemical reactor performance. In addition, several of their potentiostats are also capable of performing electrochemical impedance spectroscopy measurements with a frequency range from 10µHz to 10 MHz at a maximum load of 10V and 6A. The latter enables us to determine the internal resistances in the reactors and device strategies to lower them.

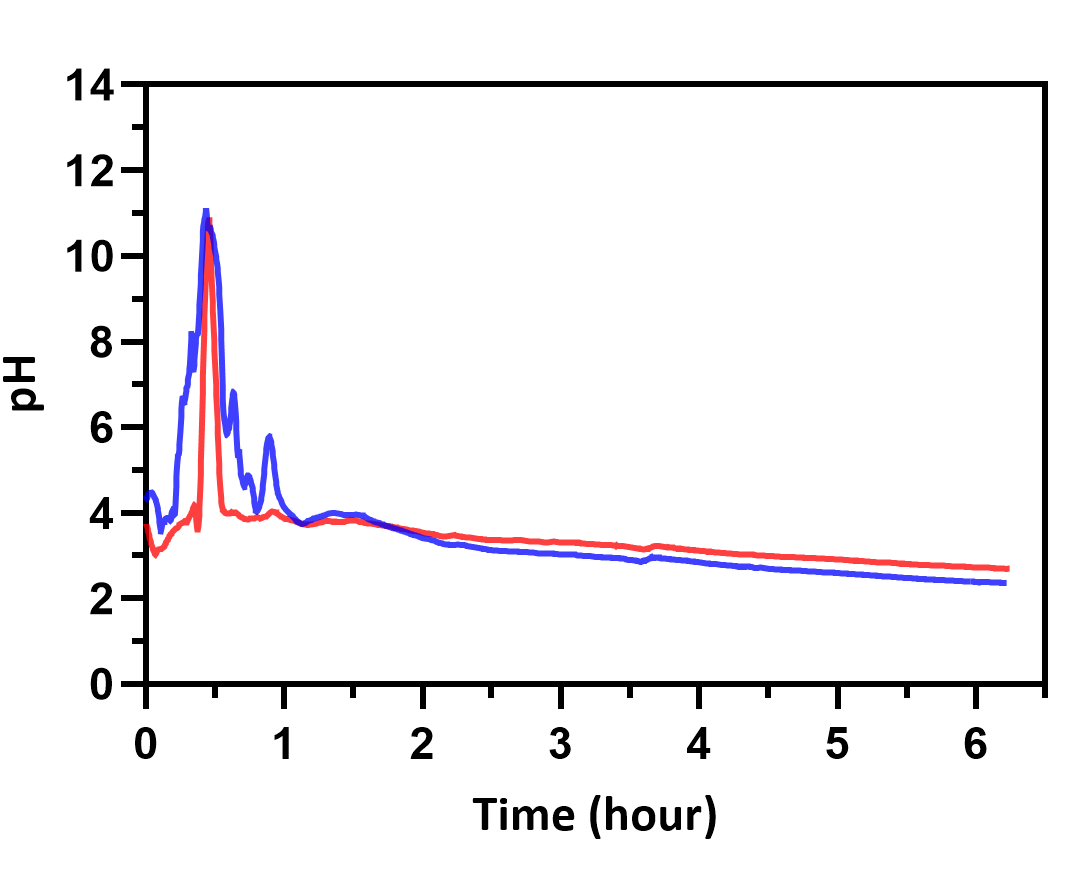

Besides for monitoring current, potential and resistance of its in-house developed reactors, ELCAT also has the required infrastructure (T sensors and pH meters) to accurately follow pH and T profiles of the reactors in real time.

Besides for monitoring current, potential and resistance of its in-house developed reactors, ELCAT also has the required infrastructure (T sensors and pH meters) to accurately follow pH and T profiles of the reactors in real time.

Finally, given that product selectivity is an important parameter for any chemical reactor, it is also important to follow product composition and its evolution along the process. In this respect, ELCAT currently possesses several gas and liquid chromatographs to follow and analyze the product outlet of any kind of reactor and determine its composition (both gas and liquid phase). In addition, it also has a GC (FID or TCD detector) and LC-MS capable of identifying unknown products in gas and/or liquid reactor outlets.

Finally, given that product selectivity is an important parameter for any chemical reactor, it is also important to follow product composition and its evolution along the process. In this respect, ELCAT currently possesses several gas and liquid chromatographs to follow and analyze the product outlet of any kind of reactor and determine its composition (both gas and liquid phase). In addition, it also has a GC (FID or TCD detector) and LC-MS capable of identifying unknown products in gas and/or liquid reactor outlets.

To be able to prepare, treat and store electrocatalysts and other samples sensitive to air, ELCAT has acquired a MB-Unilab Plus SP glovebox from MBraun in 2021 with the following specifications:

- Gas purification system to work under controlled atmosphere with < 1 ppm oxygen and moisture;

- 1,5 user workstation;

- Fully automatic 1-filter column gas circulation system for cleaning inert gas and to absorb O2 and H2O;

- System operating under Ar and regeneration under 5%H2 in Ar, fully automated system

- Two antechambers (biggest chamber has a diameter of 390 mm and length of 600 mm)

- Solvent contamination removal unit

- Feed-through for electro-chemical experimentations

To be able to prepare, treat and store electrocatalysts and other samples sensitive to air, ELCAT has acquired a MB-Unilab Plus SP glovebox from MBraun in 2021 with the following specifications:

- Gas purification system to work under controlled atmosphere with < 1 ppm oxygen and moisture;

- 1,5 user workstation;

- Fully automatic 1-filter column gas circulation system for cleaning inert gas and to absorb O2 and H2O;

- System operating under Ar and regeneration under 5%H2 in Ar, fully automated system

- Two antechambers (biggest chamber has a diameter of 390 mm and length of 600 mm)

- Solvent contamination removal unit

- Feed-through for electro-chemical experimentations

Sputter Coater

For the preparation of metallic and carbon coatings on various electrode substrates, ELCAT is equipped with a physical vapor deposition sputter coater (brand + model), capable of accurately depositing (multi)layers of single metals or combinations of two metals. It has the following specifications:

- Materials that can be deposited: C, Pt, Au, Ir, Cu, Ag, Sn, etc;

- Sputter chamber that can be simultaneously loaded with 3 targets;

- Two different elements can be deposited simultaneously to which end the coater is equipped with one DC and one RF sources;

- Substrate size can vary between 10 x10 and 200 x 200 mm and layer thickness between <10 and > 100 nm; layer uniformity meets > 100 nm layer +/-5% excluding the edge zones.