Our mission

The research group Applied Electrochemistry and Catalysis (ELCAT) is active in the field of electrochemical engineering and more specifically in the domain power-to-X-to-power. The core research activities within ELCAT are related to the development of state-of-the art electrochemical reactors and catalysts, with a view towards large-scale industrial development in the field of industrial electrification, in a green and sustainable way to ultimately replace the traditional chemical processes. Their research can be subdivided in three main topics, which are interrelated: (i) electrosynthesis (ii) electrochemical reactor engineering, and (iii) electrocatalysis. ELCAT’s main focus is thus to develop, validate or scale up original conversion technologies that either produce chemicals (e.g. H2, CO, C2H4, etc.) utilizing emission-free electricity and renewable feedstock (power-to-X) or produce renewable electricity starting from a circular feedstock (X-to-power).

From our research topics, two major aspects of our identity as a group clearly come to the surface: (i) industrial application and (ii) sustainable chemistry. It is our hope that by working on the different levels from the (electro)catalyst (fundamental research) to the actual reactor (applied research), in the future industrial processes can be adapted to the environmentally more friendly electrochemical approach, rather than by the conventional chemical processes. An important driving force herein, is the extended engineering infrastructure, which ELCAT has in its possession, and can exploit to fabricate and up-scale their own electrolyzers from scratch.

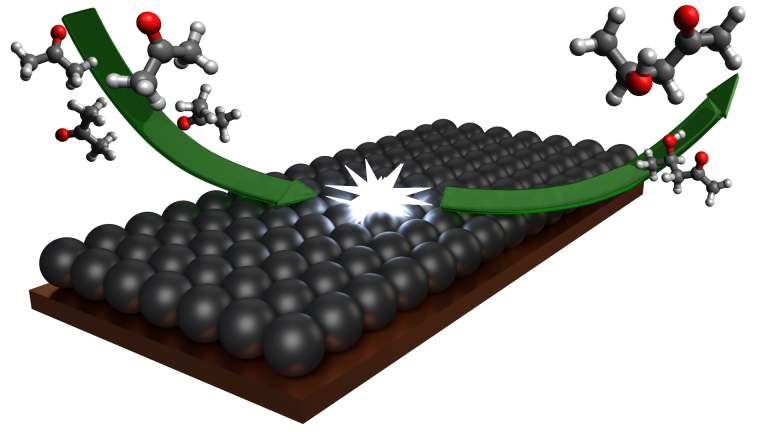

Electrosynthesis

The first main topic, electrosynthesis, deals with the electrochemical production of organic chemicals. Applying a current opens up the possibility to pursue alternative synthesis routes, which are generally of a more environmentally benign nature. Indeed, by using electrons as an energy source to initiate the reaction, the need for high temperatures or pressures can be avoided. Moreover, using electrocatalysts and modifying the potential, the selectivity can be precisely controlled towards a specific product, eliminating the need for subsequent downstream processing, which would otherwise increase the synthesis cost and energy demands.

Electrochemical Reactor Engineering

The second main topic, electrochemical reactor engineering, combines the electrochemical aspects of activity one and two into possible industrial applications. Through the development and optimization of innovative reactors, power consumption, selectivity and production levels can be improved. Mass transport and fluid handling, when not taken care of, diminish the properties of any excellent electrocatalyst. Only when the intrinsic reaction and mass transfer kinetics are matched, an economically viable process can be established. Constructing these reactors in-house, tailored to the fundamental operating behavior of the electrocatalytic nanoparticles, allows to identify the bottlenecks and grants the possibility to properly adapt the reactor components.

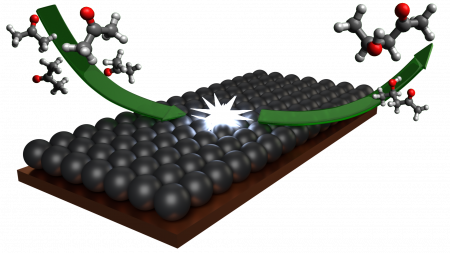

Electrocatalysis

The third main topic, electrocatalysis, embodies the synthesis of electrocatalytic particles, necessary to lower the overpotential while at the same time improving/maintaining the desired catalytic selectivity towards the target product and stability to keep performing under long-term operation. Several approaches are used to improve the catalytic performance including: (i) downsizing (to the nm scale); (ii) shifting to bimetallic alloy and/or core-shell nanoparticles; and (iii) improving performance through utilization of (active) 3D carbon supports. Using electrochemical screening methodologies in combination with surface characterization techniques such as tomography, the physicochemical nature of these particles is linked with their activity (overpotential), selectivity (product distribution) and stability (morphology changes).