Design

Program

Create

The strength of engineering

At ELCAT different types of reactors are utilized in the different application fields going from CO2 electrolyzers to fuel cells and also to redox flow batteries all of which are equipped with specifically tailored electrodes to fit the application. What’s unique about this, is that all these reactors and the separate components are designed and fabricated in-house, allowing us a faster and more accurate optimization of each component such that it can serve its specific target. Developing a reactor (component) typically starts with an initial discussion and thorough literature survey, ultimately resulting in a first CAD design and subsequently a first rendering of the overall reactor, with a visualization in 3D. Once a final design is obtained, the reactor can be fabricated. To this end, a wide variety of machinery and tools, are available at ELCAT, including a CNC micromilling machine, high-resolution 3D printers (plastic and metal), indirect casting technique, and our state of the art 5-axis femtosecond micromachining laser. With this infrastructure ELCAT is capable of making reactors from sub-meter down to the micrometer scale for a broad range of applications. On top of that the micromachining laser further enables us to modify and improve the surface structure of the reactor compounds down to the nanoscale, resulting in greatly improved performances in terms of reactivity and mass transfer. Once fabricated, ELCAT also possesses of the required expertise and facilities to test, characterize and finally further fine-tune and optimize the reactors to suit each specification.

The road of innovation

Given ELCAT’s strong background and infrastructure in the field of reactor engineering from small (1 cm²) to medium scale (> 200 cm²), it can be a strong asset for your company’s in such a way that it can develop novel reactors for your current applications and/or improve existing ones to ensure enhanced performance. Our team is prepared to collaborate with your company to grow to new stages of innovation and is able to match your needs by using our multipurpose equipment and our specialized expertise.

The strength of engineering

At ELCAT different types of reactors are utilized in the different application fields going from CO2 electrolyzers to fuel cells and also to redox flow batteries all of which are equipped with specifically tailored electrodes to fit the application. What’s unique about this, is that all these reactors and the separate components are designed and fabricated in-house, allowing us a faster and more accurate optimization of each component such that it can serve its specific target. Developing a reactor (component) typically starts with an initial discussion and thorough literature survey, ultimately resulting in a first CAD design and subsequently a first rendering of the overall reactor, with a visualization in 3D. Once a final design is obtained, the reactor can be fabricated. To this end, a wide variety of machinery and tools, are available at ELCAT, including a CNC micromilling machine, high-resolution 3D printers (plastic and metal), indirect casting technique, and our state of the art 5-axis femtosecond micromachining laser. With this infrastructure ELCAT is capable of making reactors from sub-meter down to the micrometer scale for a broad range of applications. On top of that the micromachining laser further enables us to modify and improve the surface structure of the reactor compounds down to the nanoscale, resulting in greatly improved performances in terms of reactivity and mass transfer. Once fabricated, ELCAT also possesses of the required expertise and facilities to test, characterize and finally further fine-tune and optimize the reactors to suit each specification.

The road of innovation

Given ELCAT’s strong background and infrastructure in the field of reactor engineering from small (1 cm²) to medium scale (> 200 cm²), it can be a strong asset for your company’s in such a way that it can develop novel reactors for your current applications and/or improve existing ones to ensure enhanced performance. Our team is prepared to collaborate with your company to grow to new stages of innovation and is able to match your needs by using our multipurpose equipment and our specialized expertise.

Our machines and specifications

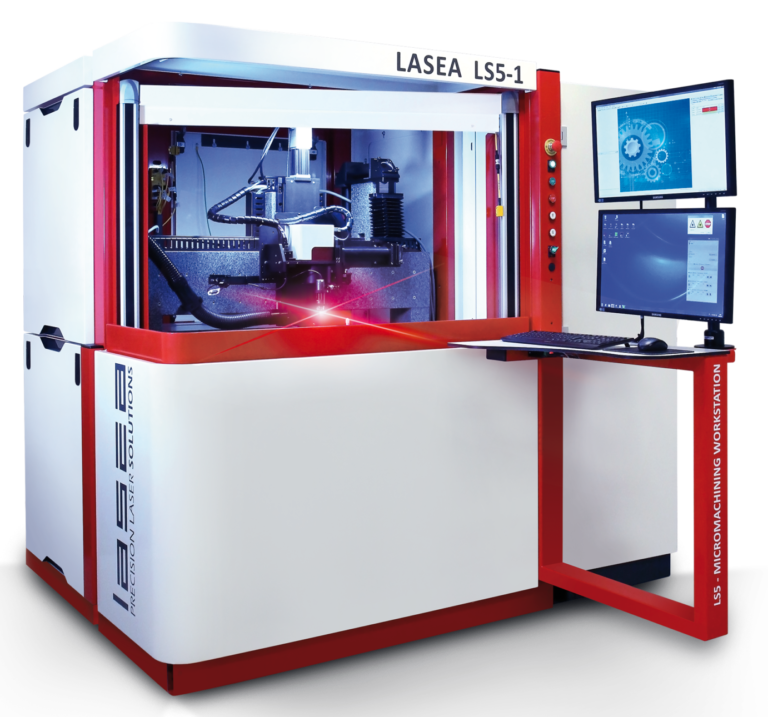

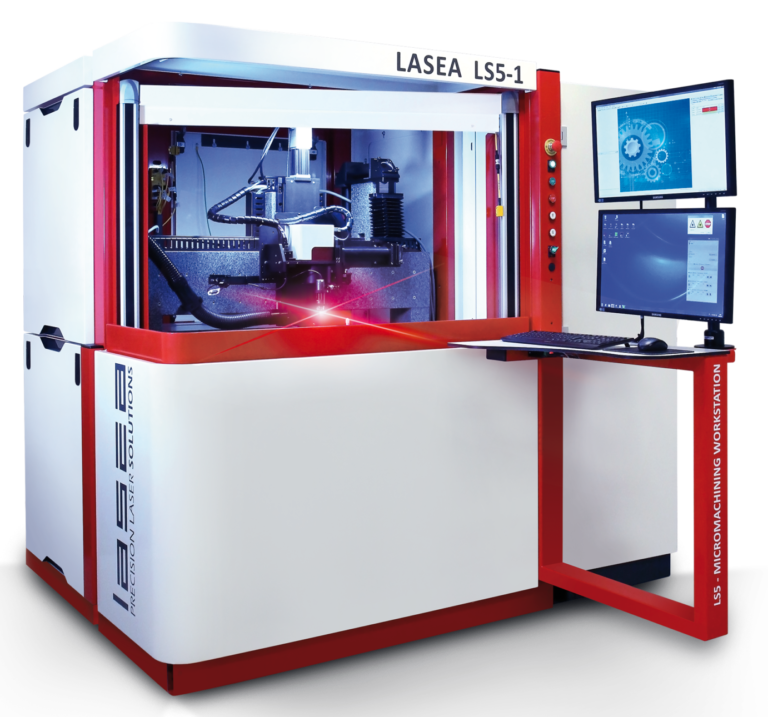

LS5-1 Accurate 3D Laser micromachining system

To precisely machine electrodes and other reactor components in 3 dimensions, ELCAT is in possession of an LS5-1 accurate 3D laser micromachining system that has the following specifications:

- High accuracy 5 axes system XYZAC 300 x 500 x 200 mm, with an XY translation speed of 500 mm/s, resolution of 0.25 µm and accuracy down to +/- 2 µm and a Z translation speed of 50 mm/s, resolution of 0.5 µm and accuracy down to +/- 10 µm;

- Air conditioning system and fume extractor;

- High precision AC rotary axis with a tilt range of -30 to -90° and an in plane rotation of 360°, a resolution of 80arc sec and an accuracy < 80 arc sec;

- 100 mm telecentric lens IR + 1 telecentric for 515 nm;

- LS-shape flex and LS-scan XY; 20

- Laser precession

- Computer-controlled automated system with Kyla software;

- Carbide femtosecond laser with an average output power of 20 W, a maximum pulse energy of 200 µJ and a wavelength of 1028 nm (+/- 5 nm). It further combines a continuously tunable repetition rate in a range of 50 kHz to 2MHz with an built in pulse picker for output pulse timing and full scale energy control with < 10 ms response time;

- Pulse duration can be tuned in a range of 290 fs – 10 ps.…

To precisely machine electrodes and other reactor components in 3 dimensions, ELCAT is in possession of an LS5-1 accurate 3D laser micromachining system that has the following specifications:

- High accuracy 5 axes system XYZAC 300 x 500 x 200 mm, with an XY translation speed of 500 mm/s, resolution of 0.25 µm and accuracy down to +/- 2 µm and a Z translation speed of 50 mm/s, resolution of 0.5 µm and accuracy down to +/- 10 µm;

- Air conditioning system and fume extractor;

- High precision AC rotary axis with a tilt range of -30 to -90° and an in plane rotation of 360°, a resolution of 80arc sec and an accuracy < 80 arc sec;

- 100 mm telecentric lens IR + 1 telecentric for 515 nm;

- LS-shape flex and LS-scan XY; 20

- Laser precession

- Computer-controlled automated system with Kyla software;

- Carbide femtosecond laser with an average output power of 20 W, a maximum pulse energy of 200 µJ and a wavelength of 1028 nm (+/- 5 nm). It further combines a continuously tunable repetition rate in a range of 50 kHz to 2MHz with an built in pulse picker for output pulse timing and full scale energy control with < 10 ms response time;

- Pulse duration can be tuned in a range of 290 fs – 10 ps.…

ELCAT has its very own MP 45, ISEL milling machine, which is capable of processing metal and polymer materials up to 40 x 40 cm with a precision down to 250 µm and a resolution of 10 µm. This milling machine can therefore be applied for the fabrication/modification of reactor components for different applications. These components can be made from a broad range of materials, such as PMMA, PEEK, PTFE, copper, aluminum, etc. using an arrange of tools from 0.3 mm to 10 mm resulting in the manufacturing of complex and precise objects.

ELCAT has its very own MP 45, ISEL milling machine, which is capable of processing metal and polymer materials up to 40 x 40 cm with a precision down to 250 µm and a resolution of 10 µm. This milling machine can therefore be applied for the fabrication/modification of reactor components for different applications. These components can be made from a broad range of materials, such as PMMA, PEEK, PTFE, copper, aluminum, etc. using an arrange of tools from 0.3 mm to 10 mm resulting in the manufacturing of complex and precise objects.

In addition to the milling machine, ELCAT also owns two types of 3D printers, which it can use to accurately print both metallic and polymer 3D reactor components from scratch.

The polymer 3D printers are an Ultimaker S3 (FDM) and the STRATASYS 3D printer (SLA), type Origin One from Stratasys and has the following specifications:

- Operates according to the digital light processing technology and includes a 4K UV projector of the digital micromirror device principle (385 & 405 nm);

- build volume of 192 x 108 x 370 mm;

- Print resolution from 50 to 100 µm in function of printing material;

- Printing speed of minimum 90 mm/hour in function of layer thickness and printing material;

The metal 3D printer is the Xact Metal 3D printer, type XM200C metal powder-bed fusion printer from Xact Metal and has the following specifications:

- Operates according to the selective laser melting technology;

- build volume of 127 x 127 x 127 mm with a tolerance < 0.1 mm;

- Heated building plate up to 100°C;

- Inert building atmosphere available (Ar);

- Layer thickness between 0,02 and 0,1mm;

- Laser type: 100W Yb fiber laser

In addition to the milling machine, ELCAT also owns two types of 3D printers, which it can use to accurately print both metallic and polymer 3D reactor components from scratch.

The polymer 3D printers are an Ultimaker S3 (FDM) and the STRATASYS 3D printer (SLA), type Origin One from Stratasys and has the following specifications:

- Operates according to the digital light processing technology and includes a 4K UV projector of the digital micromirror device principle (385 & 405 nm);

- build volume of 192 x 108 x 370 mm;

- Print resolution from 50 to 100 µm in function of printing material;

- Printing speed of minimum 90 mm/hour in function of layer thickness and printing material;

The metal 3D printer is the Xact Metal 3D printer, type XM200C metal powder-bed fusion printer from Xact Metal and has the following specifications:

- Operates according to the selective laser melting technology;

- build volume of 127 x 127 x 127 mm with a tolerance < 0.1 mm;

- Heated building plate up to 100°C;

- Inert building atmosphere available (Ar);

- Layer thickness between 0,02 and 0,1mm;

- Laser type: 100W Yb fiber laser